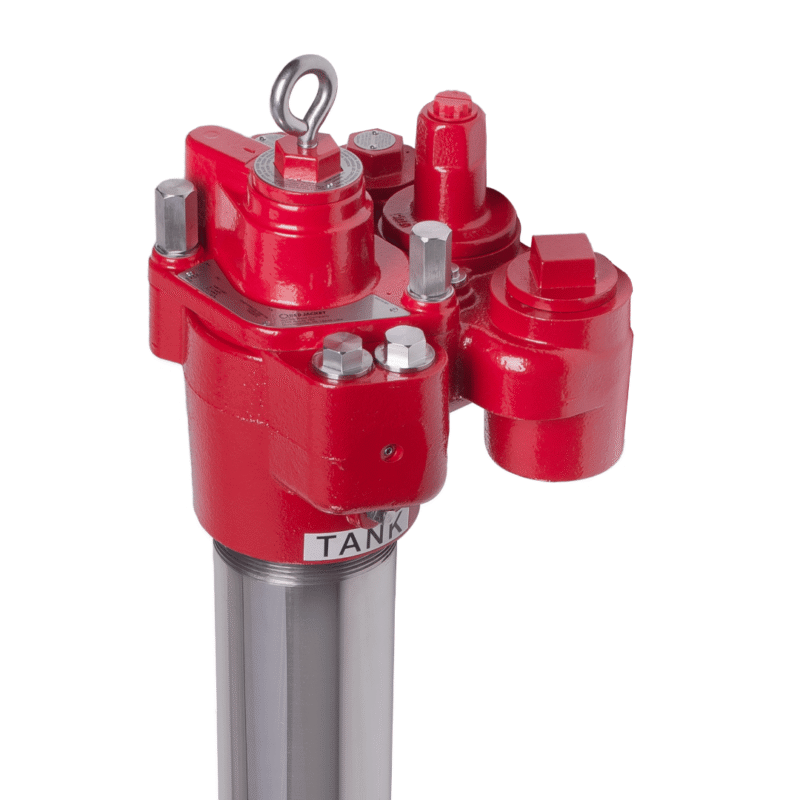

Dry Break Couplings

& Free Shipping

Free shipping on orders over $50!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Clean, Quick, and Spill-Free Transfers for High-Risk Fuel Operations

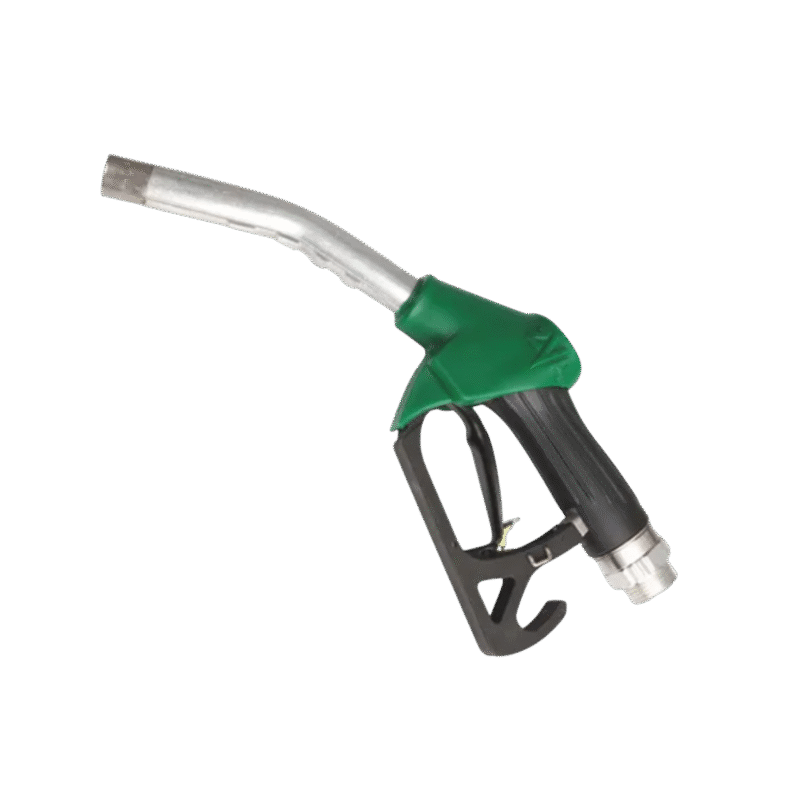

Dry Break Couplings are high-performance connectors designed to prevent fuel leakage and vapor release during connection and disconnection. Widely used in tanker trucks, depots, and refueling stations, these couplers ensure environmental safety and operator protection when transferring volatile fuels, chemicals, or lubricants.

Key Features:

Leak-Proof Disconnection: Engineered with automatic shut-off valves that prevent product spillage during uncoupling.

Robust Construction: Available in anodized aluminum, stainless steel, or brass—built to endure harsh industrial and petroleum environments.

Quick Connect & Release: Twist-lock or push-to-connect designs offer fast handling with minimal downtime.

Pressure & Flow Control: Optional open/close indicators and pressure-relief systems enhance process safety and visibility.

Corrosion-Resistant Seals: Fitted with Viton®, PTFE, or EPDM seals—compatible with petrol, diesel, biodiesel, aviation fuels, and DEF.

Specifications (Typical Range):

Sizes: 1″ to 4″

Working Pressure: Up to 25 bar (varies by model)

Temperature Range: -20°C to +80°C

Connection Types: ISO, API, NATO standards available

Applications:

Bottom and top loading of road tankers

Depot-to-depot fuel transfers

Railcar loading/unloading

Aircraft refueling systems

Chemical loading bays

Why Choose Flaw Proof’s Dry Breaks?

Reduce environmental risk, protect staff, and maintain flow efficiency. With our Dry Break Coupling systems, downtime is minimized, and compliance with safety regulations is built in by design.

Reviews

There are no reviews yet.